RUIZHOU CNC Leather Cutting Machine-cutting process for footwear industry mass production

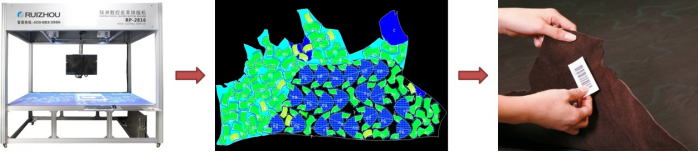

Ruizhou Intelligent nesting center is composed of three major parts: AI smart computer, Ruizhou operating system and automatic leather nesting software (PWAN). The leather contour and defects can be captured by large vision projector or high-definition camera and identify by software algorithm. With the help of our powerful nesting system (PWAN) and costing system, it can conduct automatic nesting and calculating accurate costs. Cutting direction can be adjusted randomly according to leather texture which reduces the loss and increases the utilization rate of materials.

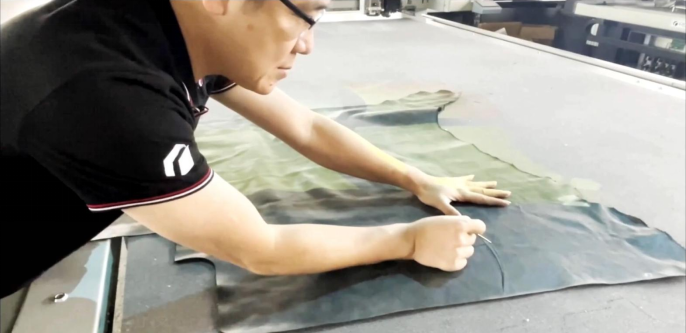

①. Material checking (Leather checker, 1 person)

— Check the defects on leather;

— Paste lables on defects part.

②Nesting (PC operator, 1 person)

— Take picture of the leather;

— System gets digital data of the lether, the outline of the leather, the defects;

— Devide material into different sections according to its quality;

— Software starts counting and automatic nesting;

— Save nesting file, name it and past barcode on the leather.

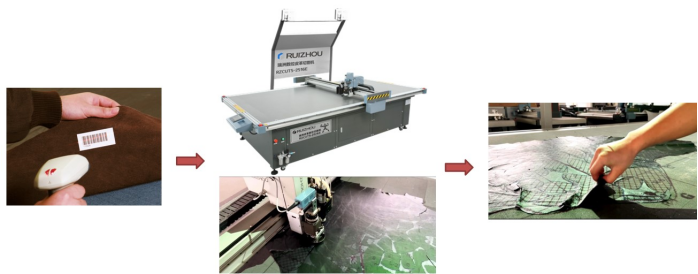

③.Machine cutting (Machine operator, 2 persons)

— Put material on machine table;

— Scan the barcode to download the nesting file;

— Machines starts cutting;

— Pick up the pieces.