Will CNC Cardboard Cutters Transform Carton Production?

2025-02-21 22:00Will CNC Cardboard Cutters Transform Carton Production?

The packaging industry is undergoing a significant transformation, with innovations such as CNC cardboard cutters, automatic box cutter machines, carton cutter machines, and corrugated cardboard cutting machines leading the way. These technologies are revolutionizing the process of cutting and assembling cardboard into boxes, driving efficiency and reducing operational costs. As businesses increasingly demand customized and high-quality packaging, these advanced cutting tools have become essential to remain competitive in an evolving market.

The Evolution of Carton Production with CNC Cardboard Cutter

The CNC cardboard cutter plays a central role in modern carton production. This advanced technology allows manufacturers to achieve high-precision cuts while minimizing waste. Traditional manual cutting methods often lead to inconsistent results and increased material wastage, leading to higher production costs. In contrast, CNC cardboard cutters ensure precise cuts, optimize material usage, and reduce waste.

What sets CNC cardboard cutters apart from other cutting tools is their ability to be programmed with complex designs. This flexibility allows businesses to create intricate box patterns with ease. Whether manufacturers need simple straight cuts or more detailed designs, CNC cardboard cutters offer unmatched precision and versatility, streamlining the production process and enhancing overall efficiency.

CNC cardboard cutters make it easier to produce custom-sized boxes. Creating boxes with specific dimensions used to be a labor-intensive process, but now it’s much simpler, especially for industries that require packaging for irregularly shaped products, such as e-commerce businesses.

The Role of Automatic Box Cutter Machines in Speed and Efficienc

Another important technology in carton production is the automatic box cutter machine. This machine automates the process of cutting and forming cardboard into boxes, eliminating the need for manual labor. In the past, workers had to manually cut and fold cardboard to form boxes, a time-consuming process prone to human error. With automatic box cutter machines, this entire process is automated, leading to faster, more accurate production.

The automatic box cutter machine operates at high speeds, allowing businesses to scale up their operations and produce large quantities of boxes quickly. This increased speed and efficiency are crucial for industries with high packaging demands, such as food and beverage companies or consumer goods manufacturers. By automating the cutting process, companies can reduce labor costs and improve consistency in the final product.

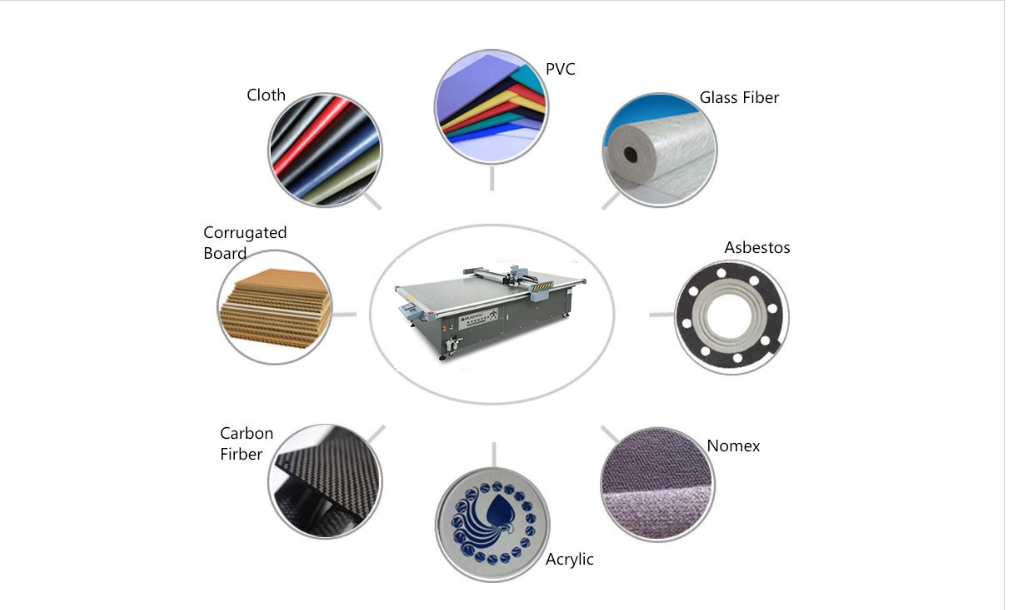

automatic box cutter machines are designed to work with various types of cardboard, including corrugated cardboard, which is thicker and more durable than standard cardboard. This versatility makes automatic box cutter machines suitable for a wide range of packaging applications, further boosting their value in any production line.

Versatility and Precision in packaging

A crucial machine for enhancing the precision and efficiency of carton production is the carton cutter machine. The carton cutter machine is designed to handle various types of cardboard, including corrugated cardboard. By incorporating advanced cutting technologies, carton cutter machines ensure accurate cuts, which reduces material waste and improves efficiency.

The carton cutter machine can be programmed to handle a variety of cuts, from simple straight lines to complex shapes. This makes it an essential tool in industries such as logistics, e-commerce, and manufacturing, where custom-sized boxes are often required. The machine’s ability to work with different thicknesses of cardboard, including corrugated cardboard, ensures the strength and durability of the finished product.carton cutter machines into the production line, companies can enhance customization, making their packaging solutions more effective at protecting products during shipping. This level of precision not only reduces material waste but also increases production efficiency.

Precision for Strength and Durability

Cutting corrugated cardboard—a material known for its strength and durability—requires special attention to detail. Corrugated cardboard cutting machines are specifically designed to handle this material, ensuring precise cuts without damaging the cardboard's structure.

Unlike regular cardboard, corrugated cardboard is thicker and more rigid, which can make cutting it more challenging. However, with corrugated cardboard cutting machines, manufacturers can achieve clean, accurate cuts that maintain the integrity of the material. These machines are capable of handling high-volume production runs, making them ideal for industries that require bulk packaging solutions.

One of the key advantages of corrugated cardboard cutting machines is their ability to integrate seamlessly with other machines, such as the automatic box cutter machines. This creates a fully automated production process that improves efficiency, reduces errors, and ensures high-quality products.

Streamlining Production: The Integration of Multiple Machines

The real benefits of these advanced cutting technologies come when they are integrated into a single, streamlined production line. By combining CNC cardboard cutters, automatic box cutter machines, carton cutter machines, and corrugated cardboard cutting machines, manufacturers can optimize their production process from start to finish.

For example, a CNC cardboard cutter can be used to create intricate designs and patterns, while a corrugated cardboard cutting machine cuts large sheets of corrugated cardboard into smaller panels. These panels are then fed into the automatic box cutter machine, which assembles the panels into finished boxes, a carton cutter machine ensures that the boxes are accurately cut to the required size and shape.

This integrated approach minimizes the need for manual intervention, ensuring that each step of the process is executed with precision. Companies can produce high-quality boxes with greater efficiency, meeting the demands of their customers more effectively.

Benefits of Automation: Cost Savings and Sustainability

The adoption of CNC cardboard cutters, automatic box cutter machines, carton cutter machines, and corrugated cardboard cutting machines offers significant cost-saving advantages. These machines are designed to reduce material waste, increase cutting accuracy, and speed up production times.Manufacturers can save on raw materials, labor, and time, ultimately improving their bottom line.

These machines also help manufacturers achieve sustainability goals. By optimizing the use of materials and reducing waste, companies can produce packaging in an environmentally friendly way. As businesses face increasing pressure to reduce their environmental impact, CNC cardboard cutters, automatic box cutter machines, and carton cutter machines offer a smart way to reduce waste while increasing profitability.

In the future, we may see CNC cardboard cutters integrated with artificial intelligence to automatically adjust cutting parameters based on real-time data, further enhancing efficiency.carton cutter machine could feature sensors that detect defects in cardboard before it’s cut, ensuring higher-quality boxes are produced.

As these technologies continue to evolve, businesses will have more opportunities to streamline production, reduce costs, and meet the growing demand for high-quality, custom packaging solutions.