The cutting machine can actually cut this

2024-09-21 16:07cnc rubber asbestos silicone foam PDFE gaskets cutter system oscillating knife cutting machine

Brief introduction for CNC Gasket Cutting Machine

Our advanced CNC Gasket Cutting Machine is designed for precision cutting of a wide range of gasket materials, including asbestos, rubber, and other industrial-grade components. Utilizing state-of-the-art computer numerical control (CNC) technology, this machine ensures high accuracy and efficiency, making it an ideal solution for industries requiring detailed and precise gasket fabrication. Whether for automotive, aerospace, or industrial applications, our CNC Gasket Cutting Machine delivers unmatched performance and reliability.

Parameters

Model of cutting machine | RZCRT5-1510E |

Effective working area | 1500mm×1000mm |

Cutting speed | 0-1200mm/s |

Cutting thickness | 0-25mm ( customized cutting machine can up to 50mm) |

Our Advantages | 1.A whole piece aluminum platform 2.Welding stable machine structure 4.Safety device |

Method of fixing material | Divisional vacuum absorption |

Knife | Oscillating blade head, Milling Cutter, Hobbing Cutter, Creasing Wheel |

Pen type | Common signing pen, Oil pen, ball-point pen, Silver pen |

Human Machine Interface (HMI) | Touch screen LCD |

Machine resolution | 0.01mm |

Software resolution | 0.025mm |

Interface of transmission | Network port |

| Command system | HP-GL and GP-GL compatible formats |

| Gearing | Linear guide and gear rack |

Motor | Servo motor |

Machine Working Voltage | 220V |

Air pump power | 5.5KW |

Energy saving device | Frequency converter |

| Safety device | Automatic laser device |

Software system | Independent research and development CNC software |

Control system | Cutting table and computer display |

Tools and its functions of RZCRT5-1510E

1. Electric Oscillating Knife Tool (EOT)

It is suitable for cutting medium-density materials.

-For various of flexible materials

-Amplitudes are optional.

2. Pneumatic Oscillating Knife Tool (POT)

It is an air-driven tool particularly well suited for

cutting tough, high-density materials but can also handle

soft, thicker ones, maximum amplitude can reach to 8mm.

Six advantages of RZCRT5-1510E

1. High Precision Cutting: Achieves intricate and complex designs with exceptional accuracy, minimizing material waste and ensuring optimal performance of gaskets.

2. Versatile Material Handling: Capable of cutting a wide range of materials, including asbestos, rubber, and composite gaskets, catering to diverse industrial needs.

3. Enhanced Efficiency: Automates the cutting process, significantly reducing production time and labor costs while maintaining consistent quality.

4. User-Friendly Interface: Features an intuitive control panel with easy-to-use software, allowing operators to quickly set up and execute cutting tasks with minimal training.

5. Durable Construction: Built with high-quality components to withstand rigorous industrial use, ensuring long-term reliability and minimal maintenance requirements.

6. Customizable Options: Offers flexibility in machine configurations and cutting parameters to meet specific production requirements and enhance operational efficiency.

Packaging of Our cutting machines

The cnc automatic cutting machines are packaged with standard export wooden case, which can guarantee your machine safety.

Our Company

Guangdong RUIZHOU Technology Co., Ltd is a national Torch Plan High-tech Enterprise, specialized in the research, development, sales and technique service of soft material intelligent CNC cutting machine.

RUIZHOU Technology has been dedicated in supplying informationized and automatic design and whole solution of intelligent production for a broad community of soft material manufacturers, which achieves the realization of the confluence of informatization and industrialization.

Certifications

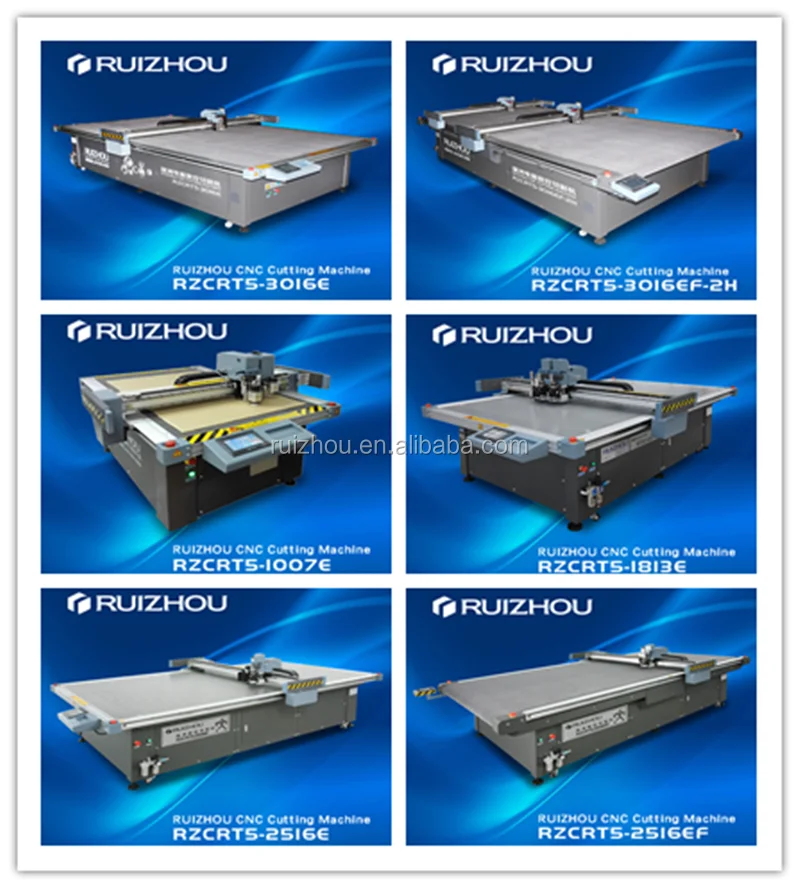

Related products

contact us:

https://ruizhou.en.alibaba.com

https://www.ruizhoutech.com