Shoemaking industry

Projecting the cutting graphics image through the projector can reflect the layout position of the graphics in real time. The layout is efficient and fast, saving time, effort and materials.

Double cutter heads cut at the same time, doubling the efficiency. Meet the production goals of small batches, multiple orders, and multiple styles.

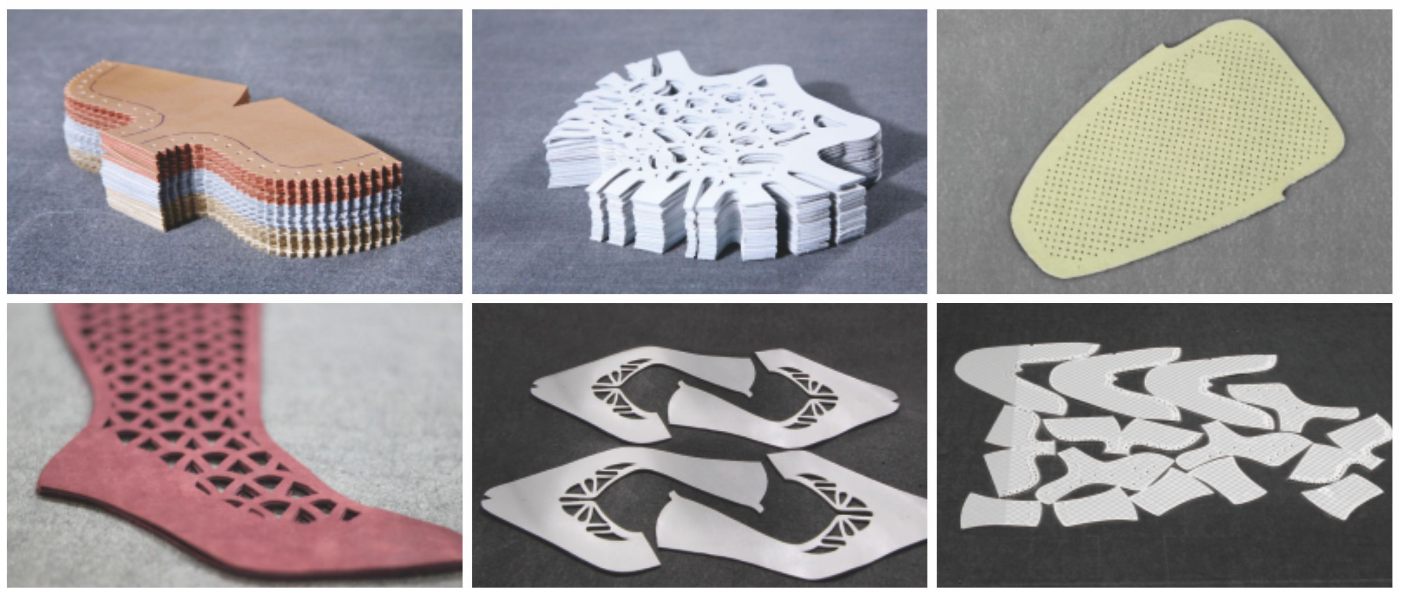

It has a wide range of uses and can be used for cutting leather and other flexible materials. Widely used in shoemaking industry, luggage industry, decoration industry, etc.

Programmable multi-axis motion controller, stability and operability reach the leading technical level at home and abroad. The transmission system of the cutting machine adopts imported linear guide rails,

racks, and synchronous belts, and the cutting accuracy completely reaches zero error from the origin to and from the origin.

Friendly high-definition touch screen human-machine interface, convenient to operate and easy to learn. Standard RJ45 network data transmission, fast speed, stable and reliable transmission.

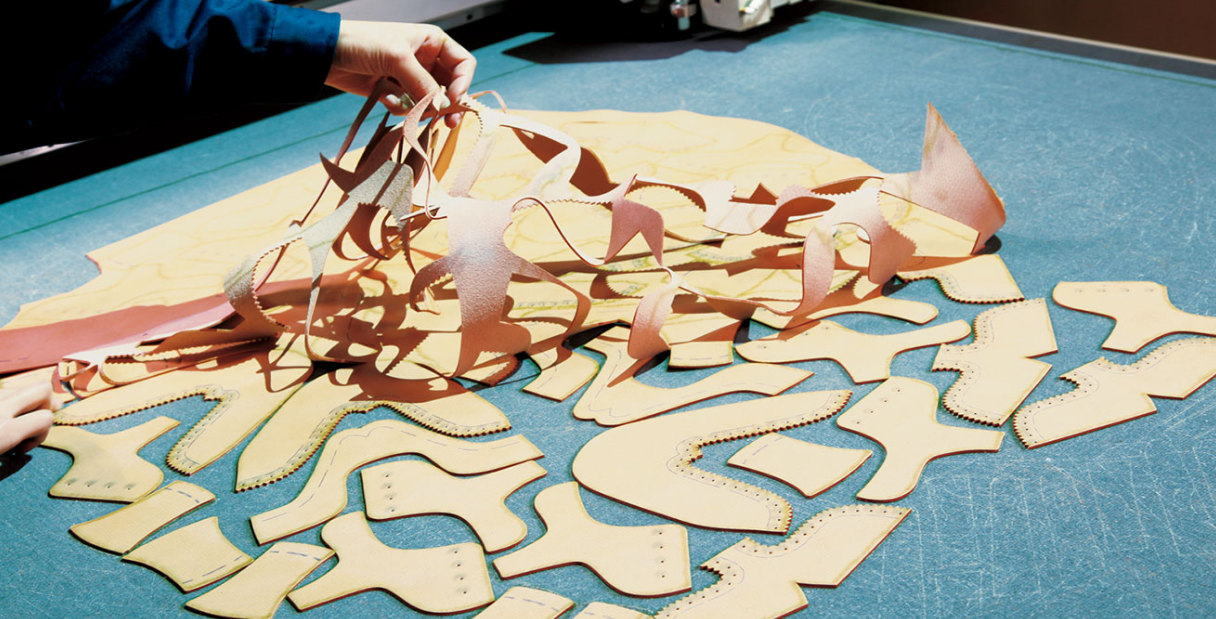

Trial cutting material

Any special-shaped material, detailed cutting

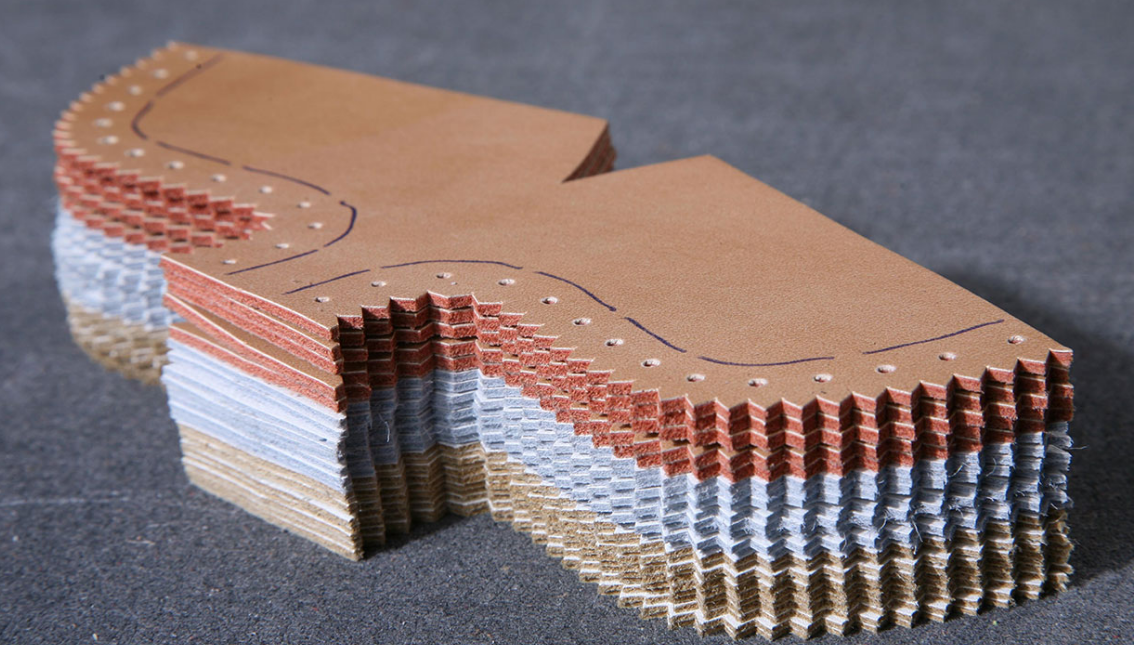

Production process

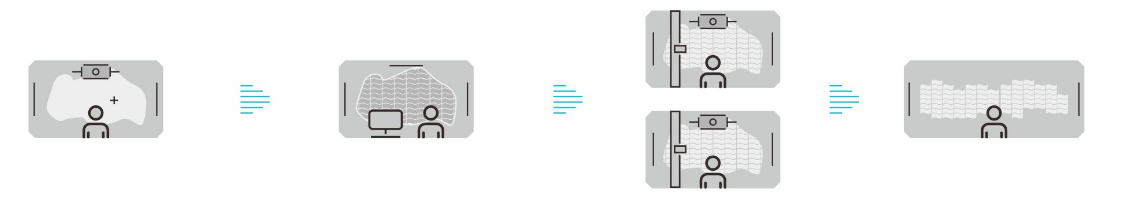

One person and one machine can complete all material cutting, saving labor costs

Four intelligent leather cutting production modes

1.Skin test

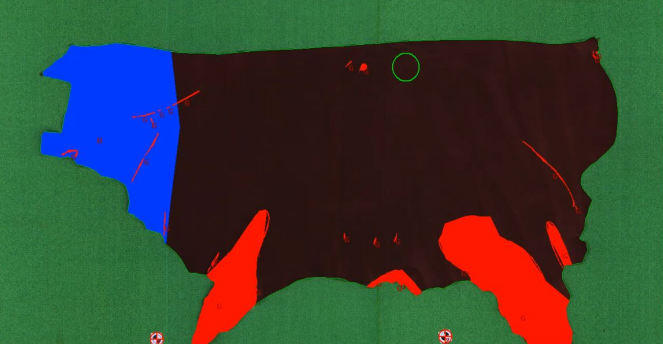

Check according to different leather materials

Draw the defective part

2. Identify flaws

One-click intelligent identification of leather defects and leather contours, contour imaging and zoning

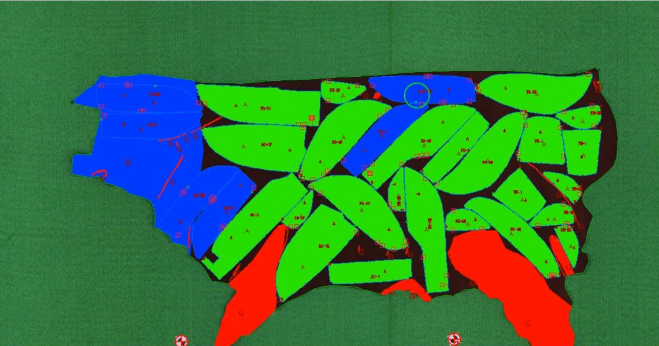

3. Intelligent typesetting

Ruizhou core technology online fully automatic intelligent typesetting improves production efficiency and saves time

4.Double knife cutting

Double-beam and double-blade cutting improves cutting efficiency. Line drawing, hole punching, half-blade and full-blade cutting can be completed in one go.

Small batch production solutions

Faced with the prevailing situation in today's market of "more styles and less quantity", companies must achieve a balance between productivity and profitability. The computer numerical control leather cutting system provides a solution for mass production. The production-to-volume approach involves more batches, fewer orders, and saves material storage. When receiving orders of different quantities, you can flexibly consider automated continuous production or quantitative manual typesetting. The combination of CCD camera tracking and positioning, suspended large-vision projection system, rolling table top, dual-operation machine head and other hardware truly provides intelligent cutting solutions for companies of different sizes.

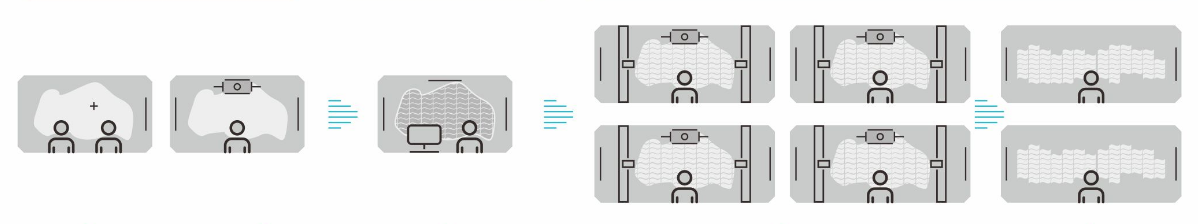

Large quantitiesProduction solutions

In view of the large order quantity of enterprises, Ruizhou CNC leather cutting system CUT series leather automatically carries out typesetting, labeling and recording typesetting information. The recorded data can be shared with the cutting machine to achieve seamless docking, ensure the continuous operation of the machine, and provide guarantee for enterprises to achieve orderly digital production management. Intelligent leather cutting process: leather identification scanning area (the latest Ruizhou AI leather defect identification scanning system is built), intelligent typesetting cutting area of Ruizhou CNC leather cutting machine, and material receiving and sorting area, forming automatic linkage conveying and creating intelligence.An ecological system capable of digitize leather cutting.

CONTACT US:

https://www.ruizhoutech.com