Efficient and fast, time-saving, labor-saving and material-saving clothing digital cutting system

2024-10-10 18:00

● Projecting the cutting graphic image through the projector can reflect the layout position of the graphics in real time. The layout is efficient and fast, saving time, effort and materials.

● Widely used, it can be used for cutting leather and other flexible materials. Widely used in shoemaking industry, clothing industry, luggage industry, automobile industry, decoration industry, etc.

● Meet the production goals of small batches, multiple orders, and multiple styles. Programmable multi-axis motion controller, stability and operability reach the leading technical level at home and abroad.

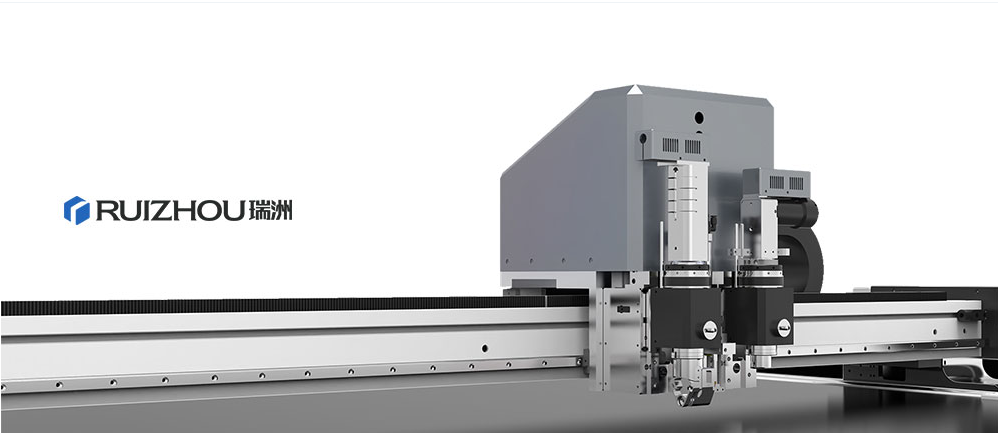

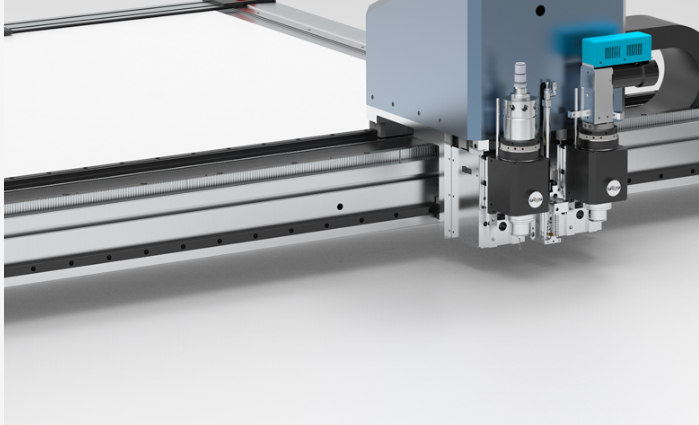

● The transmission system of the cutting machine adopts imported linear guide rails, racks and synchronous belts, and the cutting accuracy reaches zero error from the origin to and from the origin.

● Friendly high-definition touch screen human-machine interface, convenient to operate and easy to learn. Standard RJ45 network data transmission, fast speed, stable and reliable transmission.

● The F machine model is equipped with a rolling conveyor belt, which can cut continuously to achieve seamless production goals that meet the production goals of small batches, multiple orders, and multiple styles.

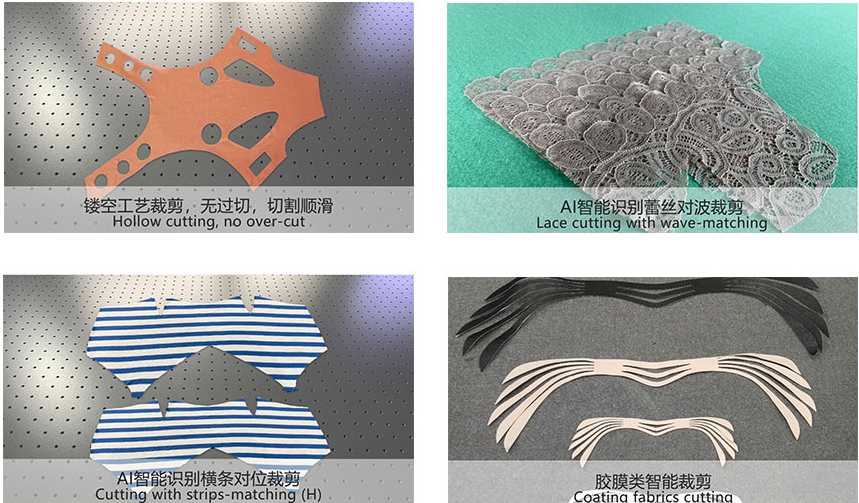

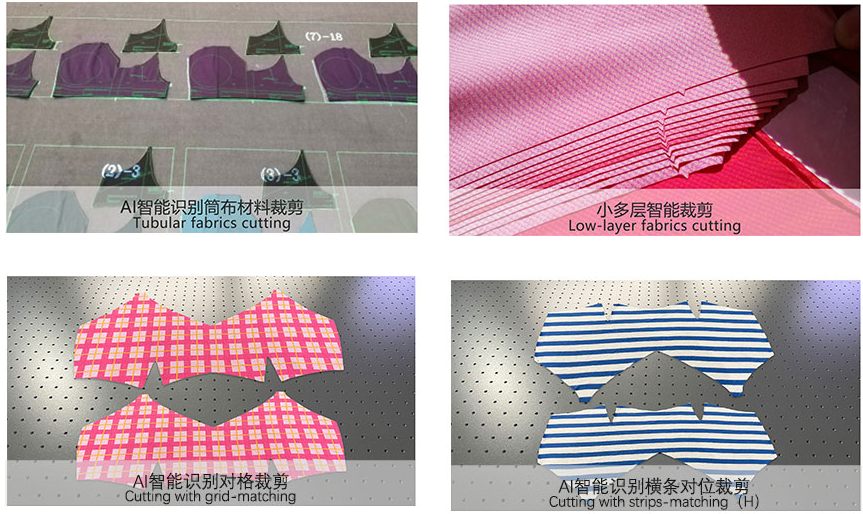

● The clothing industry is equipped with an automatic typesetting system for strips and grids, and standard cutting of grid fabrics.

Effective cutting area Accessories and scanning area Machine dimensions

2500MM*1600MM(continuous cutting) 2700MM*1600MM 8785MM*2715MM*2320MM

Cuttiing speed Receiving area Feeding speed

0MM/S-1000MM/S 2500MM*1600MM 0MM/S-300MM/S

cutting material:Automated cutting needs for various knitted variable pattern fabrics such as lace underwear, underwear, printing, swimwear, printed film, fashion, suit customization, etc.

Trial cutting material

--------

Any special-shaped material, detailed cutting

More than 20 years of core research and development

More innovative, faster and more flexible

Fast and stable tool with all components precisely coordinated with each other

Different cutter heads are configured according to the needs of various processing materials.

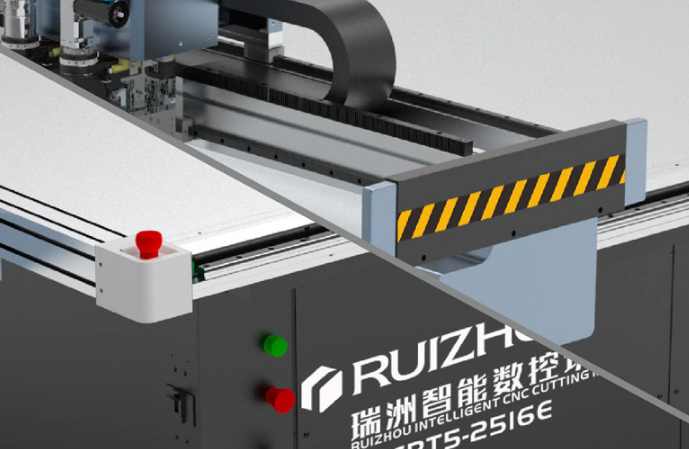

Safety is the last word

Safety, safety, safety, safety

Emergency stop devices and safety infrared sensing devices are installed at the four corners

to ensure maximum protection of the operator's safety during

the high-speed movement of the machine.

brand partners

contact us:

https://www.ruizhoutech.com