Is the CNC Fabric Cutter the Future of Textile Cutting?

2025-03-11 22:00The textile industry has always been one of the most dynamic sectors, constantly evolving to meet the growing demands for speed, precision, and cost-effectiveness. In recent years, technology has played a crucial role in revolutionizing the way textiles are cut, with one innovation standing out: the CNC fabric cutter. As manufacturers and designers alike strive for greater efficiency, it’s important to explore whether the CNC fabric cutter could indeed be the future of textile cutting.

What is a CNC Fabric Cutter?

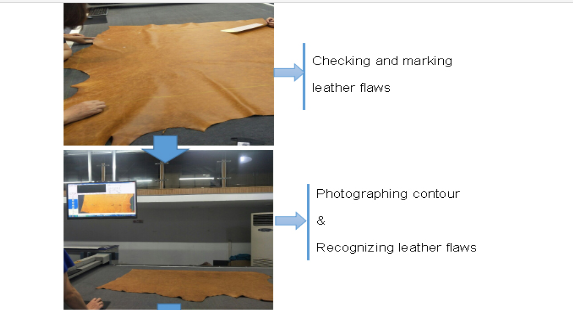

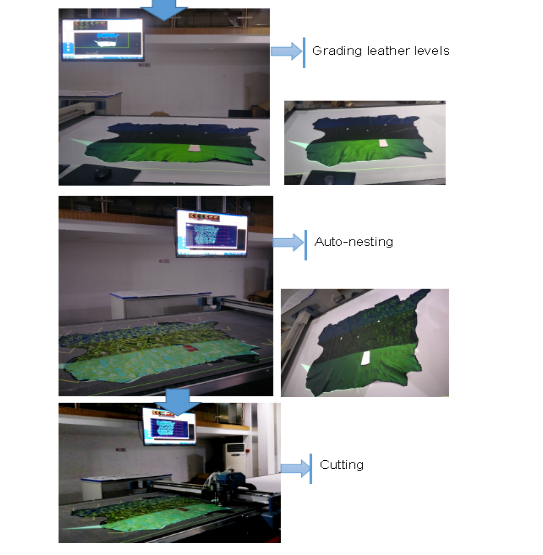

CNC or Computer Numerical Control, refers to a machine that is operated through computer programming. The CNC fabric cutter utilizes a similar technology to automate the fabric cutting process, which traditionally required labor-intensive manual efforts. This machine is equipped with sharp blades, knives, or lasers that are controlled precisely by a computer, enabling it to cut fabric with exceptional accuracy and speed. Compared to traditional fabric cutting methods, a fabric cutter can streamline operations, reduce material waste, and enhance production quality.

Evolution of Fabric Cutting Machines

The cutting of fabric has been a highly manual process. Garment manufacturers and textile factories often relied on skilled workers to cut fabric by hand, which, while precise, was slow and could lead to significant material wastage. As demand for faster production cycles and increased quality control grew, the industry began turning to more automated solutions.

One of the earliest advancements was the introduction of fabric cutting machines, which allowed for faster, more accurate cuts than manual methods. These machines, machines were often limited in their capabilities. They typically required more operator intervention, were slower than modern systems, and lacked the precision that is now required in the competitive textile industry.

The advent of CNC technology, however, marked a revolutionary shift in the capabilities of fabric cutters. Today’s CNC fabric cutters can not only follow complex cutting patterns but also adapt to variations in fabric type and thickness, providing a high level of flexibility for manufacturers.

How CNC Fabric Cutters Are Changing the Industry

CNC fabric cutters are having a profound impact on the textile industry by transforming how companies approach cutting fabric. These machines are designed to work with a variety of materials, including cotton, silk, polyester, wool, and more, allowing manufacturers to produce a wide range of textile products with greater efficiency.

One of the key advantages of CNC fabric cutters is their precision. These machines can cut complex patterns with millimeter-perfect accuracy, reducing the need for post-production corrections. This precision ensures that garment cutting machines can maintain consistent quality, even when processing intricate or customized designs.

The use of CNC fabric cutters significantly reduces labor costs. With fewer manual processes involved, manufacturers can reduce their dependence on skilled labor for fabric cutting. The integration of a CNC fabric cutter into a production line can lead to greater automation, further lowering operational costs and increasing overall productivity.

Benefits Over Traditional Fabric Cutters

Speed and Efficiency

CNC fabric cutters work at much faster speeds than manual cutters. By automating the cutting process, they enable manufacturers to complete projects more quickly, reducing production time and increasing output.

Reduced Material Waste

The precise cutting ability of CNC fabric cutters helps to minimize material waste, which is a critical factor for cost efficiency. Traditional fabric cutters often result in waste, especially when working with intricate patterns or when there is a lack of consistent cutting precision.

Cost Savings

While the initial investment in a CNC fabric cutter can be high, the long-term benefits are significant. Over time, reduced labor costs, improved speed, and decreased material waste translate to greater overall savings for manufacturers.

Customization and Flexibility

The CNC fabric cutter offers greater flexibility when it comes to cutting various types of fabric. Whether the material is delicate or tough, a CNC machine can be programmed to adjust its cutting methods accordingly, providing greater versatility for manufacturers.

The Impact of CNC Fabric Cutters on Garment Cutting Machines

Garment cutting machines, which are used to cut fabrics into specific shapes for garment production, are also benefiting from the advancements made by CNC fabric cutters. CNC technology enables garment cutting machines to be more efficient, accurate, and flexible in handling various fabric types and garment designs.

With the introduction of CNC fabric cutters, garment cutting machines are now able to work seamlessly with digital design files, improving both the speed and accuracy of the cutting process. This automation reduces the chance of errors in the cutting process, ensuring that each piece is cut to the exact specifications of the design.

As garment production becomes more customized and fast-paced, the role of CNC fabric cutters and garment cutting machines will continue to expand. Manufacturers who adopt these technologies will be better positioned to meet the rising demand for fast and precise garment production.

Understanding Cloth Cutter Price and Market Adoption

Despite the many advantages of CNC fabric cutters, one of the factors that often holds manufacturers back from adopting this technology is the cloth cutter price. CNC fabric cutters represent a significant upfront investment, and smaller businesses or those operating in developing regions may find the cost prohibitive.

As technology advances and more manufacturers enter the market, the price of these machines is expected to decrease. With greater demand and competition, manufacturers will find it increasingly cost-effective to invest in CNC fabric cutting technology. Furthermore, government initiatives, grants, and financing options may help to ease the financial burden for smaller businesses seeking to upgrade their production lines.

The cloth cutter price is, therefore, an important consideration, but over time, the long-term savings in operational efficiency and reduced material waste will likely outweigh the initial investment. As the industry grows and embraces innovation, the adoption of CNC fabric cutters is expected to become more widespread, particularly as the cost of the technology continues to decrease.

While traditional tools like sewing cutting tables and garment cutting machines will still hold value, the integration of CNC fabric cutters will pave the way for a new era in textile production. The potential to reduce material waste, increase output, and lower costs will ensure that CNC fabric cutters are an essential investment for textile manufacturers in the years to come.